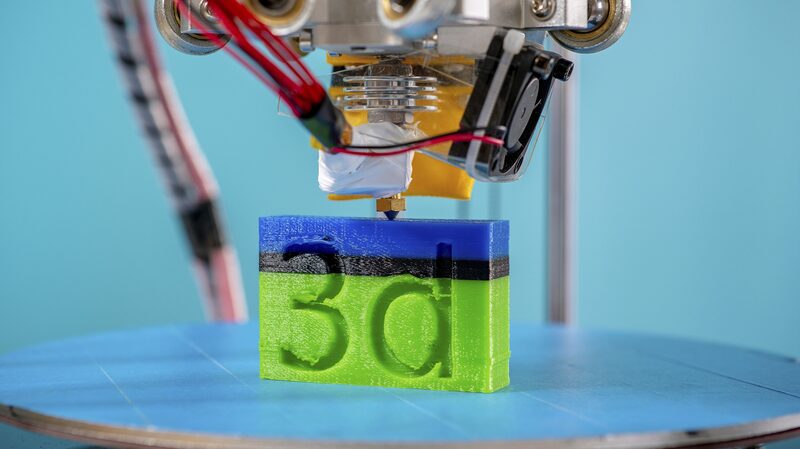

Hey tech enthusiasts! 🎉 Big news coming out of east China! Researchers from Zhejiang University in Hangzhou have just flipped the script on 3D printing. They've developed elastomers that are not only 3D printable but also boast exceptional strength and toughness! 💪

Published in the prestigious journal Nature 🏆, this breakthrough could be a total game-changer for manufacturing high-performance products. Professor Wu Jingjun, one of the masterminds behind the research, says this could overcome the material limitations that have been holding 3D printing back. Talk about leveling up! 🚀

We all know 3D printing is super cool for making complex, customized designs. But let's be real—it’s been struggling with slow print speeds and materials that just aren't tough enough for mass production. 🐢

Well, that's about to change! Recent advances in ultra-fast 3D printing of photopolymers have sped things up, but the materials still weren't as strong as those made with traditional methods. Enter the Zhejiang University team! 🧑🔬👩🔬

\"To make 3D printing tech fit for more scenarios, we needed to tweak the material properties,\" explains researcher Fang Zizheng. And tweak they did! They cooked up a new 3D photo-printable resin that results in an elastomer with a tensile strength of 94.6 MPa and toughness of 310.4 MJ/m3. That's off the charts compared to any other 3D-printed elastomer! 📈

To put it to the test, they printed a humble rubber band. But this isn't your average office supply! This rubber band could stretch up to nine times its original length and handle a tensile strength of 94 MPa without snapping. 😱

But wait, there's more! They also created balloons with epic puncture resistance using the new material. Imagine balloons that won't pop at the first sign of a tack! 🎈🛡️

This innovation could be the catalyst that propels 3D printing into new industries and applications. From stronger wearable tech to resilient automotive parts, the possibilities are endless! 🌐

Stay tuned, because the future of 3D printing just got a whole lot stronger! 💥

Reference(s):

Researchers develop 3D printable elastomers with exceptional strength

cgtn.com